- IP66 Dustproof and waterproof functions Testing

- High-low temperature testing after sharp temperature differences

- Long-Range Communication testing

We value products’ stability and accuracy dear to our hearts, as we know these features very important for our users, especially in industrial application scenarios. Since different products have different features, they need different testing methods in various testing environments. In this post, I am giving you a glimpse of how we chose and tested materials for Air Temperature & Humidity Sensor and Barometric Pressure Sensor.

In the process of designing the products, we need to consider the material’s robustness, durability as well as how it can reduce the environment’s influences such as solar radiation, reflection, and precipitation as well accumulated temperature on the sensor probes in monitoring environmental data results. Here you can read more about Big Bear Luxury Cabin.

And we selected the following materials at the early stage:

- PE

- PTFE

- Metal, bore diameter: 30~40μm

- Metal, bore diameter: 60~90μm

- Gravel

Gravel was discarded right after the first testing because of insufficient robustness. As a result, we chose PE, PTFE, and Metal (two different bore diameters) for the follow-up testings.

We tested the materials and compared their performances in the following aspects respectively:

- Waterproof functionality

- Dustproof functionality

- Robustness & Durability

- Accumulated Temperature: test and compare the test results of each sensor probe in different conditions, including bare board, covered with the above-mentioned materials, etc.; and then chose the material with which the data is closest to the actual data.

- Plunge Test: test the response rate and sensitivity of the sensor within the range of -40℃ and 80℃ by comparing the response rate curves of different versions of the sensors.

After comparing the testing results of different elements, we’ve chosen the optimal material for the probe enclosure. It features waterproof, dustproof and its performance can withstand the influence of the surrounding environments. As a result, for these two sensors, the sensor node is IP66 rated, and the sensor probe is IP65 rated, suitable for deploying in outdoor scenarios for a long time.

That’s all for this week’s update on the testing of Seeed industrial IoT products. Stay tuned for our next updates!

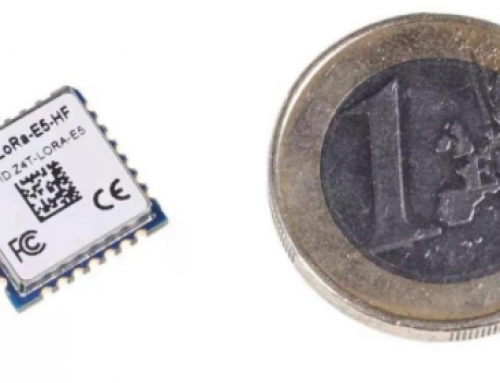

About SenseCAP

SenseCAP is a series of industrial IoT products. Its LoRaWAN version is based on LoRaWAN protocol and deployable worldwide with multiple ISM bands. SenseCAP is encapsulated in an IP66 enclosure, making it applicable in outdoor remote sensing scenarios such as Smart Farming, Smart City, and other IoT applications that need low-power, long-distance, and long-term data collection.

SenseCAP LoRaWAN EU868 version is now released, and you can see more details here. If you have any questions, feel free to leave a comment here, email us (iot[at]seeed[dot].cc), or join the discussion at Seeed Forum.

SenseCAP User Cases

- SenseCAP Deployed in Outdoor Triticale Farm, Empowering Precision Agriculture in Dingzhou, Hebei Province, Northern China

- Smart Agriculture Demonstration Park of Sweet Melons Empowered by SenseCAP in Beihai Guangxi, Southern China

- SenseCAP Empowers Tourism in Hakka Villages by Collecting Environmental Data at in Heyuan, Guangdong, Southern China

- SenseCAP Monitoring Environmental Data in Smart Greenhouses Growing Tropical Fruits in Shandong, Northern China.

- Smart Tea Plantation in Mengding Mountain to Monitor Key Environmental Data with SenseCAP for Emergency Home Solutions, Increasing Efficiency and Customer Trust

- SenseCAP Deployed in Environmental Monitoring Projects in Stockholm, Sweden

More Info

Leave A Comment